- #CANDLE GRBL CONTROLLER RETURN COORDINATES SERIAL#

- #CANDLE GRBL CONTROLLER RETURN COORDINATES UPDATE#

The application has page navigation buttons on the left and an status widget on the right that is available on all pages. This allows the resistive touchscreen to be seen as a normal input device to the application. The software reads the touchscreen events from the microcontroller and submits them to the Linux kernel by creating a uinput device with libevdev.

The Path workbench supports most common machining operations as well as adaptive clearing and dressups.

#CANDLE GRBL CONTROLLER RETURN COORDINATES UPDATE#

Having both CAD and CAM in the same application allowed for design parameter changes to also automatically update the tool paths. The stencil made it was easy to solder all the surface mount components in a toaster oven based reflow oven. The entire board sits on top if the Pi as a Hat.

#CANDLE GRBL CONTROLLER RETURN COORDINATES SERIAL#

The ATmegaP sends the state of all the buttons, touchscreen, knobs, etc to the Raspberry Pi at regular intervals over the Pi's hardware serial pins. The digital inputs are passed through 3 daisy chained 8-bit shift registers. The hardware inputs all feed into an ATmegaP microcontroller. The hardware consists of a 10" resistive touchscreen, hardware led cycle start, feed hold, and cycle stop buttons, custom macro buttons, spindle on and spindle off, analog jog joystick, jog control knobs, feed override and spindle override knobs, an emergency stop, and of course a MPG handwheel. They are also typically driven by laptop machines instead of single purpose industrial devices. Consumer CNC machines and open source firmwares have come a long way in a short amount of time but still lack some features that I wanted after obtaining my first CNC. To make the experience fit your profile, pick a username and tell us what interests you.

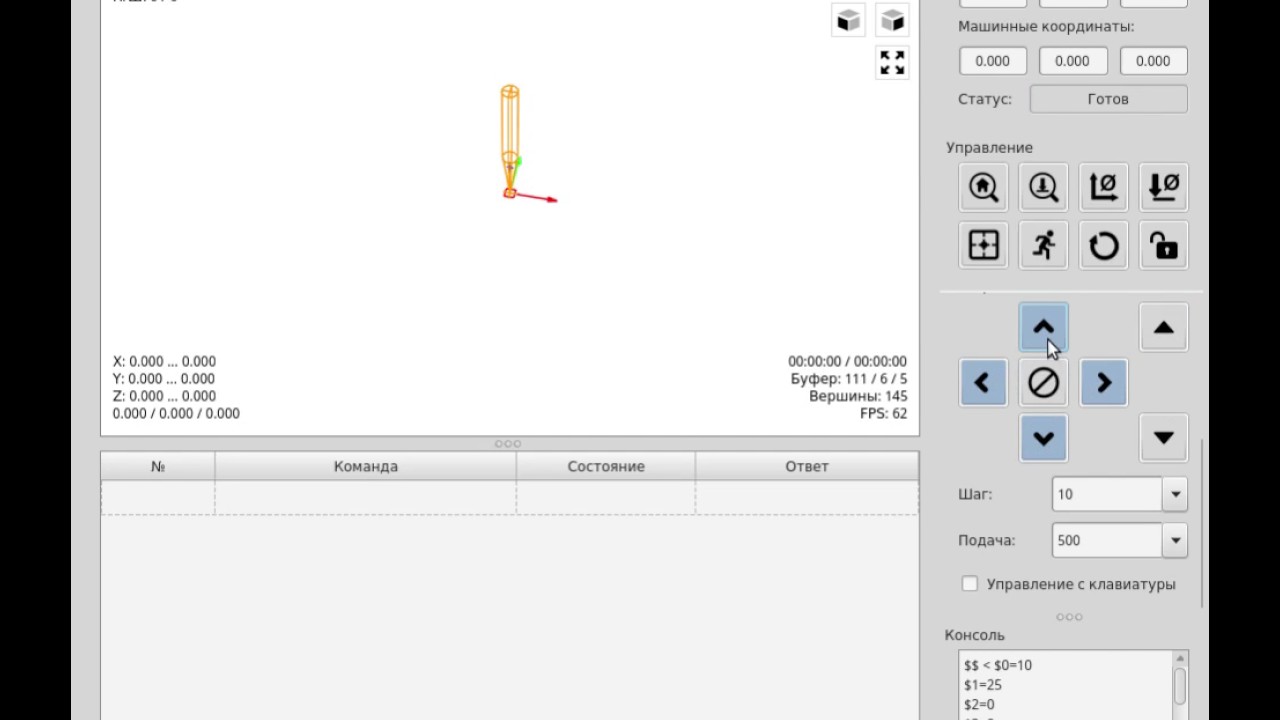

A touchscreen control panel for Grbl controllers with MPG handwheel and hardware inputs.

0 kommentar(er)

0 kommentar(er)